How to Choose Off-the-Shelf Power Resistors

I. Introduction

In the world of electronics, power resistors play a crucial role in managing electrical energy. These components are designed to handle significant amounts of power, making them essential in various applications, from power supplies to motor controls. Selecting the right power resistor is vital for ensuring the reliability and efficiency of your electronic designs. This article aims to guide you through the process of choosing off-the-shelf power resistors, covering their types, specifications, sourcing, and testing.

II. Understanding Power Resistors

A. What are Power Resistors?

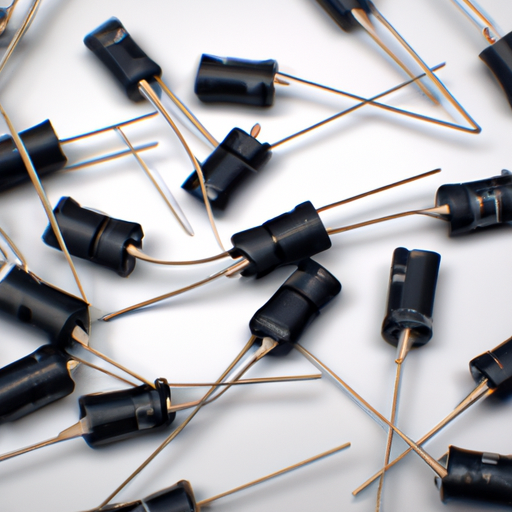

Power resistors are components that limit the flow of electrical current in a circuit while dissipating energy in the form of heat. They are designed to handle higher power levels than standard resistors, making them suitable for applications where heat generation is a concern.

1. Function and Applications

Power resistors are used in various applications, including:

Voltage dividers: To reduce voltage levels in circuits.

Current sensing: To measure current flow by creating a known voltage drop.

Load testing: To simulate loads in testing environments.

Motor control: To manage the speed and torque of electric motors.

2. Types of Power Resistors

Power resistors come in several types, each with unique characteristics:

Wirewound Resistors: Made by winding a metal wire around a core, these resistors offer high precision and power ratings.

Thick Film Resistors: These resistors are made by applying a thick layer of resistive material onto a substrate, providing good stability and low cost.

Thin Film Resistors: Known for their high accuracy and low noise, thin film resistors are made by depositing a thin layer of resistive material.

B. Key Specifications of Power Resistors

When selecting a power resistor, it’s essential to understand the key specifications:

1. Resistance Value

The resistance value, measured in ohms (Ω), determines how much current will flow through the resistor for a given voltage.

2. Power Rating

The power rating, expressed in watts (W), indicates the maximum power the resistor can dissipate without overheating. Exceeding this rating can lead to failure.

3. Tolerance

Tolerance refers to the allowable deviation from the specified resistance value, typically expressed as a percentage. A lower tolerance indicates higher precision.

4. Temperature Coefficient

This specification indicates how much the resistance value changes with temperature. A lower temperature coefficient is preferable for applications requiring stability across varying temperatures.

5. Voltage Rating

The voltage rating specifies the maximum voltage that can be applied across the resistor without risk of breakdown.

III. Factors to Consider When Choosing Power Resistors

A. Application Requirements

1. Load Conditions

Consider whether the load conditions are constant or variable. For variable loads, ensure the resistor can handle fluctuations in power.

2. Environmental Conditions

Evaluate the environmental conditions, such as temperature and humidity, as these factors can affect resistor performance.

B. Electrical Characteristics

1. Resistance Value and Tolerance

Choose a resistance value that meets your circuit requirements, and consider the tolerance based on the precision needed for your application.

2. Power Rating and Derating

Select a power rating that exceeds the expected load. It’s also wise to derate the resistor (use it at a lower power level) to enhance reliability.

3. Voltage Rating and Surge Capability

Ensure the voltage rating is sufficient for your application, and consider the resistor's ability to handle voltage surges.

C. Physical Characteristics

1. Size and Form Factor

The physical size of the resistor can impact your design. Ensure it fits within the available space in your circuit.

2. Mounting Options

Consider whether you need through-hole or surface mount resistors based on your PCB design.

3. Heat Dissipation and Thermal Management

Evaluate how the resistor will dissipate heat. Proper thermal management is crucial to prevent overheating.

D. Reliability and Lifespan

1. Failure Modes and Mechanisms

Understand the potential failure modes of the resistor, such as thermal runaway or mechanical failure.

2. Manufacturer Reputation and Quality Assurance

Choose resistors from reputable manufacturers known for quality assurance and reliability.

IV. Types of Power Resistors and Their Applications

A. Wirewound Resistors

1. Characteristics and Advantages

Wirewound resistors offer high power ratings and excellent stability, making them suitable for high-precision applications.

2. Common Applications

They are commonly used in power supplies, audio equipment, and industrial applications.

B. Thick Film Resistors

1. Characteristics and Advantages

Thick film resistors are cost-effective and provide good performance in a compact size.

2. Common Applications

They are widely used in consumer electronics, automotive applications, and telecommunications.

C. Thin Film Resistors

1. Characteristics and Advantages

Thin film resistors offer high accuracy and low noise, making them ideal for precision applications.

2. Common Applications

They are often used in medical devices, instrumentation, and high-frequency applications.

D. Other Specialized Resistors

1. Characteristics and Advantages

Specialized resistors, such as ceramic and metal oxide, offer unique properties for specific applications.

2. Common Applications

These resistors are used in high-temperature environments, power electronics, and specialized industrial applications.

V. Sourcing Off-the-Shelf Power Resistors

A. Identifying Reputable Suppliers

1. Online vs. Local Distributors

Consider both online and local distributors for sourcing resistors. Online platforms often provide a broader selection, while local distributors can offer immediate availability.

2. Manufacturer Certifications and Standards

Check for manufacturer certifications and adherence to industry standards to ensure quality.

B. Comparing Product Specifications

1. Using Datasheets Effectively

Datasheets provide essential information about resistor specifications. Learn to read and interpret these documents to make informed decisions.

2. Understanding Part Numbers and Codes

Familiarize yourself with part numbers and codes to identify the right resistor for your needs.

C. Evaluating Cost vs. Performance

1. Budget Considerations

While cost is a factor, prioritize performance and reliability over the lowest price.

2. Long-Term Value vs. Initial Cost

Consider the long-term value of the resistor, including its lifespan and reliability, when evaluating cost.

VI. Testing and Validation

A. Importance of Testing Power Resistors

Testing ensures that the selected resistors meet performance expectations and specifications.

B. Methods for Testing Performance

1. Bench Testing

Conduct bench tests to evaluate the resistor's performance under real-world conditions.

2. Simulation Tools

Use simulation tools to model resistor behavior in your circuit before implementation.

C. Ensuring Compliance with Industry Standards

Verify that the resistors comply with relevant industry standards to ensure safety and reliability.

VII. Conclusion

Choosing the right off-the-shelf power resistor is a critical step in the design and implementation of electronic circuits. By understanding the types, specifications, and factors to consider, you can make informed decisions that enhance the performance and reliability of your applications. Always consult with experts when in doubt, and remember that careful selection can save time and resources in the long run.

VIII. References

For further information on power resistors, consider exploring the following resources:

- Manufacturer datasheets and technical documents

- Industry standards from organizations like the IEEE and IEC

- Books and articles on electronic component selection and design

By following this guide, you can navigate the complexities of selecting power resistors and ensure that your electronic designs are robust and efficient.

How to Choose Off-the-Shelf Power Resistors

I. Introduction

In the world of electronics, power resistors play a crucial role in managing electrical energy. These components are designed to handle significant amounts of power, making them essential in various applications, from power supplies to motor controls. Selecting the right power resistor is vital for ensuring the reliability and efficiency of your electronic designs. This article aims to guide you through the process of choosing off-the-shelf power resistors, covering their types, specifications, sourcing, and testing.

II. Understanding Power Resistors

A. What are Power Resistors?

Power resistors are components that limit the flow of electrical current in a circuit while dissipating energy in the form of heat. They are designed to handle higher power levels than standard resistors, making them suitable for applications where heat generation is a concern.

1. Function and Applications

Power resistors are used in various applications, including:

Voltage dividers: To reduce voltage levels in circuits.

Current sensing: To measure current flow by creating a known voltage drop.

Load testing: To simulate loads in testing environments.

Motor control: To manage the speed and torque of electric motors.

2. Types of Power Resistors

Power resistors come in several types, each with unique characteristics:

Wirewound Resistors: Made by winding a metal wire around a core, these resistors offer high precision and power ratings.

Thick Film Resistors: These resistors are made by applying a thick layer of resistive material onto a substrate, providing good stability and low cost.

Thin Film Resistors: Known for their high accuracy and low noise, thin film resistors are made by depositing a thin layer of resistive material.

B. Key Specifications of Power Resistors

When selecting a power resistor, it’s essential to understand the key specifications:

1. Resistance Value

The resistance value, measured in ohms (Ω), determines how much current will flow through the resistor for a given voltage.

2. Power Rating

The power rating, expressed in watts (W), indicates the maximum power the resistor can dissipate without overheating. Exceeding this rating can lead to failure.

3. Tolerance

Tolerance refers to the allowable deviation from the specified resistance value, typically expressed as a percentage. A lower tolerance indicates higher precision.

4. Temperature Coefficient

This specification indicates how much the resistance value changes with temperature. A lower temperature coefficient is preferable for applications requiring stability across varying temperatures.

5. Voltage Rating

The voltage rating specifies the maximum voltage that can be applied across the resistor without risk of breakdown.

III. Factors to Consider When Choosing Power Resistors

A. Application Requirements

1. Load Conditions

Consider whether the load conditions are constant or variable. For variable loads, ensure the resistor can handle fluctuations in power.

2. Environmental Conditions

Evaluate the environmental conditions, such as temperature and humidity, as these factors can affect resistor performance.

B. Electrical Characteristics

1. Resistance Value and Tolerance

Choose a resistance value that meets your circuit requirements, and consider the tolerance based on the precision needed for your application.

2. Power Rating and Derating

Select a power rating that exceeds the expected load. It’s also wise to derate the resistor (use it at a lower power level) to enhance reliability.

3. Voltage Rating and Surge Capability

Ensure the voltage rating is sufficient for your application, and consider the resistor's ability to handle voltage surges.

C. Physical Characteristics

1. Size and Form Factor

The physical size of the resistor can impact your design. Ensure it fits within the available space in your circuit.

2. Mounting Options

Consider whether you need through-hole or surface mount resistors based on your PCB design.

3. Heat Dissipation and Thermal Management

Evaluate how the resistor will dissipate heat. Proper thermal management is crucial to prevent overheating.

D. Reliability and Lifespan

1. Failure Modes and Mechanisms

Understand the potential failure modes of the resistor, such as thermal runaway or mechanical failure.

2. Manufacturer Reputation and Quality Assurance

Choose resistors from reputable manufacturers known for quality assurance and reliability.

IV. Types of Power Resistors and Their Applications

A. Wirewound Resistors

1. Characteristics and Advantages

Wirewound resistors offer high power ratings and excellent stability, making them suitable for high-precision applications.

2. Common Applications

They are commonly used in power supplies, audio equipment, and industrial applications.

B. Thick Film Resistors

1. Characteristics and Advantages

Thick film resistors are cost-effective and provide good performance in a compact size.

2. Common Applications

They are widely used in consumer electronics, automotive applications, and telecommunications.

C. Thin Film Resistors

1. Characteristics and Advantages

Thin film resistors offer high accuracy and low noise, making them ideal for precision applications.

2. Common Applications

They are often used in medical devices, instrumentation, and high-frequency applications.

D. Other Specialized Resistors

1. Characteristics and Advantages

Specialized resistors, such as ceramic and metal oxide, offer unique properties for specific applications.

2. Common Applications

These resistors are used in high-temperature environments, power electronics, and specialized industrial applications.

V. Sourcing Off-the-Shelf Power Resistors

A. Identifying Reputable Suppliers

1. Online vs. Local Distributors

Consider both online and local distributors for sourcing resistors. Online platforms often provide a broader selection, while local distributors can offer immediate availability.

2. Manufacturer Certifications and Standards

Check for manufacturer certifications and adherence to industry standards to ensure quality.

B. Comparing Product Specifications

1. Using Datasheets Effectively

Datasheets provide essential information about resistor specifications. Learn to read and interpret these documents to make informed decisions.

2. Understanding Part Numbers and Codes

Familiarize yourself with part numbers and codes to identify the right resistor for your needs.

C. Evaluating Cost vs. Performance

1. Budget Considerations

While cost is a factor, prioritize performance and reliability over the lowest price.

2. Long-Term Value vs. Initial Cost

Consider the long-term value of the resistor, including its lifespan and reliability, when evaluating cost.

VI. Testing and Validation

A. Importance of Testing Power Resistors

Testing ensures that the selected resistors meet performance expectations and specifications.

B. Methods for Testing Performance

1. Bench Testing

Conduct bench tests to evaluate the resistor's performance under real-world conditions.

2. Simulation Tools

Use simulation tools to model resistor behavior in your circuit before implementation.

C. Ensuring Compliance with Industry Standards

Verify that the resistors comply with relevant industry standards to ensure safety and reliability.

VII. Conclusion

Choosing the right off-the-shelf power resistor is a critical step in the design and implementation of electronic circuits. By understanding the types, specifications, and factors to consider, you can make informed decisions that enhance the performance and reliability of your applications. Always consult with experts when in doubt, and remember that careful selection can save time and resources in the long run.

VIII. References

For further information on power resistors, consider exploring the following resources:

- Manufacturer datasheets and technical documents

- Industry standards from organizations like the IEEE and IEC

- Books and articles on electronic component selection and design

By following this guide, you can navigate the complexities of selecting power resistors and ensure that your electronic designs are robust and efficient.