What are the Product Features of Metal Film Resistors?

I. Introduction

A. Definition of Metal Film Resistors

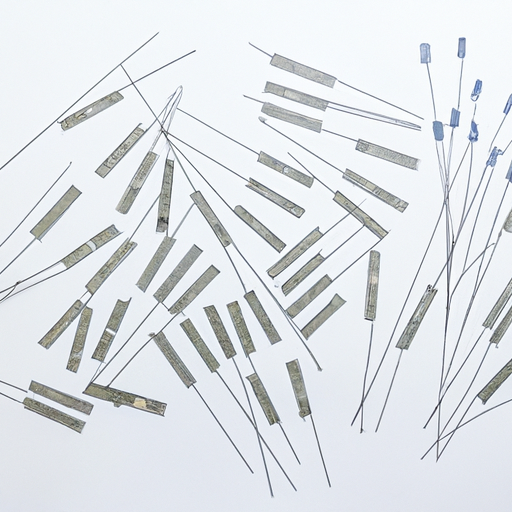

Metal film resistors are passive electronic components that provide resistance in electrical circuits. They are made by depositing a thin layer of metal onto a ceramic substrate, which is then trimmed to achieve the desired resistance value. Known for their precision and stability, metal film resistors are widely used in various electronic applications.

B. Importance in Electronic Circuits

In electronic circuits, resistors play a crucial role in controlling current flow, dividing voltages, and protecting sensitive components. Metal film resistors, in particular, are favored for their accuracy and reliability, making them essential in high-performance applications such as audio equipment, precision measurement instruments, and more.

C. Overview of the Article

This article will explore the product features of metal film resistors, including their construction, electrical characteristics, performance features, applications, advantages, and limitations. By the end, readers will have a comprehensive understanding of why metal film resistors are a preferred choice in many electronic designs.

II. Construction and Composition

A. Materials Used

1. Metal Film

The primary component of metal film resistors is a thin layer of metal, typically nickel-chromium or tantalum nitride. This metal layer is responsible for the resistor's resistance value and is deposited in a controlled manner to ensure uniformity.

2. Substrate

The substrate, usually made of ceramic, provides mechanical support and thermal stability. Ceramic substrates are chosen for their excellent insulating properties and ability to withstand high temperatures, which is crucial for maintaining performance under varying conditions.

B. Manufacturing Process

1. Thin Film Deposition

The manufacturing process begins with thin film deposition, where the metal layer is applied to the substrate using techniques such as sputtering or evaporation. This process allows for precise control over the thickness and uniformity of the metal film.

2. Laser Trimming

After deposition, the resistor is trimmed using laser technology to achieve the desired resistance value. This method allows for high precision and is a key factor in the accuracy of metal film resistors.

C. Comparison with Other Resistor Types

1. Carbon Film Resistors

Carbon film resistors are made by depositing a carbon layer on a substrate. While they are less expensive, they typically have higher noise levels and lower precision compared to metal film resistors.

2. Wirewound Resistors

Wirewound resistors consist of a wire wound around a core. They can handle higher power ratings but are bulkier and less precise than metal film resistors, making them less suitable for applications requiring high accuracy.

III. Electrical Characteristics

A. Resistance Value Range

Metal film resistors are available in a wide range of resistance values, typically from a few ohms to several megaohms. This versatility allows them to be used in various applications, from simple circuits to complex instrumentation.

B. Tolerance Levels

1. Standard Tolerances (1%, 5%)

Standard metal film resistors typically have tolerances of 1% or 5%, making them suitable for general-purpose applications where moderate precision is acceptable.

2. Precision Tolerances (0.1%, 0.5%)

For applications requiring high accuracy, precision metal film resistors are available with tolerances as low as 0.1% or 0.5%. These resistors are essential in precision measurement and calibration tasks.

C. Temperature Coefficient of Resistance (TCR)

1. Definition and Importance

The temperature coefficient of resistance (TCR) indicates how much a resistor's resistance changes with temperature. A low TCR is desirable as it ensures stable performance across varying temperatures.

2. Typical Values for Metal Film Resistors

Metal film resistors typically have a TCR of ±5 to ±50 ppm/°C, making them suitable for applications where temperature stability is critical.

IV. Performance Features

A. Stability and Reliability

1. Long-term Stability

Metal film resistors exhibit excellent long-term stability, meaning their resistance values remain consistent over time, even under varying environmental conditions.

2. Environmental Stability

These resistors are also resistant to environmental factors such as humidity and temperature fluctuations, ensuring reliable performance in diverse applications.

B. Noise Characteristics

1. Low Noise Generation

One of the standout features of metal film resistors is their low noise generation. This characteristic is particularly important in audio and precision measurement applications, where noise can significantly impact performance.

2. Comparison with Other Resistor Types

Compared to carbon film and wirewound resistors, metal film resistors produce significantly less noise, making them the preferred choice for high-fidelity audio and sensitive electronic circuits.

C. Power Rating

1. Power Dissipation Capabilities

Metal film resistors are available in various power ratings, typically ranging from 1/8 watt to several watts. This range allows them to be used in both low-power and moderate-power applications.

2. Heat Management

Effective heat management is crucial for maintaining performance. Metal film resistors are designed to dissipate heat efficiently, reducing the risk of thermal damage and ensuring longevity.

V. Applications

A. Common Uses in Electronics

1. Audio Equipment

Metal film resistors are widely used in audio equipment due to their low noise characteristics and high precision, contributing to better sound quality.

2. Precision Measurement Instruments

Instruments that require accurate measurements, such as oscilloscopes and multimeters, often utilize metal film resistors for their stability and precision.

B. Specialized Applications

1. Medical Devices

In medical devices, where accuracy and reliability are paramount, metal film resistors are commonly employed to ensure precise readings and safe operation.

2. Aerospace and Defense

The aerospace and defense industries rely on metal film resistors for their robustness and stability in extreme conditions, making them suitable for critical applications.

C. Trends in Usage

As technology advances, the demand for high-precision components continues to grow. Metal film resistors are increasingly being integrated into modern electronic designs, particularly in fields such as IoT and automotive electronics.

VI. Advantages of Metal Film Resistors

A. High Precision and Accuracy

Metal film resistors are known for their exceptional precision, making them ideal for applications where accuracy is critical.

B. Low Temperature Coefficient

Their low TCR ensures stable performance across a wide temperature range, enhancing reliability in various environments.

C. Excellent Stability Over Time

With long-term stability, metal film resistors maintain their performance characteristics, reducing the need for frequent recalibration.

D. Versatility in Applications

The wide range of resistance values and power ratings makes metal film resistors suitable for diverse applications, from consumer electronics to industrial equipment.

VII. Limitations of Metal Film Resistors

A. Cost Considerations

While metal film resistors offer numerous advantages, they are generally more expensive than carbon film resistors, which may be a consideration for budget-sensitive projects.

B. Power Handling Limitations

Metal film resistors have lower power handling capabilities compared to wirewound resistors, making them less suitable for high-power applications.

C. Size Constraints

Although they are available in various sizes, metal film resistors can be bulkier than other types, which may pose challenges in compact circuit designs.

VIII. Conclusion

A. Summary of Key Features

Metal film resistors are characterized by their precision, stability, low noise generation, and versatility. Their construction and electrical characteristics make them a preferred choice in many high-performance applications.

B. Future Trends in Metal Film Resistor Technology

As electronic devices continue to evolve, the demand for high-precision components will likely increase. Innovations in manufacturing processes and materials may further enhance the performance and applicability of metal film resistors.

C. Final Thoughts on Selection and Use in Circuit Design

When selecting resistors for electronic circuits, engineers must consider the specific requirements of their applications. Metal film resistors offer a reliable solution for applications demanding high accuracy and stability, making them an excellent choice for modern electronic designs.

IX. References

A. Suggested Reading

1. "Resistor Technology: A Comprehensive Guide" - Electronics Journal

2. "Understanding Resistor Types and Their Applications" - Circuit Basics

B. Industry Standards and Guidelines

1. IEC 60115 - Resistors for use in electronic equipment

2. EIA-198 - Standard for Resistor Specifications

By understanding the product features of metal film resistors, engineers and designers can make informed decisions that enhance the performance and reliability of their electronic circuits.

What are the Product Features of Metal Film Resistors?

I. Introduction

A. Definition of Metal Film Resistors

Metal film resistors are passive electronic components that provide resistance in electrical circuits. They are made by depositing a thin layer of metal onto a ceramic substrate, which is then trimmed to achieve the desired resistance value. Known for their precision and stability, metal film resistors are widely used in various electronic applications.

B. Importance in Electronic Circuits

In electronic circuits, resistors play a crucial role in controlling current flow, dividing voltages, and protecting sensitive components. Metal film resistors, in particular, are favored for their accuracy and reliability, making them essential in high-performance applications such as audio equipment, precision measurement instruments, and more.

C. Overview of the Article

This article will explore the product features of metal film resistors, including their construction, electrical characteristics, performance features, applications, advantages, and limitations. By the end, readers will have a comprehensive understanding of why metal film resistors are a preferred choice in many electronic designs.

II. Construction and Composition

A. Materials Used

1. Metal Film

The primary component of metal film resistors is a thin layer of metal, typically nickel-chromium or tantalum nitride. This metal layer is responsible for the resistor's resistance value and is deposited in a controlled manner to ensure uniformity.

2. Substrate

The substrate, usually made of ceramic, provides mechanical support and thermal stability. Ceramic substrates are chosen for their excellent insulating properties and ability to withstand high temperatures, which is crucial for maintaining performance under varying conditions.

B. Manufacturing Process

1. Thin Film Deposition

The manufacturing process begins with thin film deposition, where the metal layer is applied to the substrate using techniques such as sputtering or evaporation. This process allows for precise control over the thickness and uniformity of the metal film.

2. Laser Trimming

After deposition, the resistor is trimmed using laser technology to achieve the desired resistance value. This method allows for high precision and is a key factor in the accuracy of metal film resistors.

C. Comparison with Other Resistor Types

1. Carbon Film Resistors

Carbon film resistors are made by depositing a carbon layer on a substrate. While they are less expensive, they typically have higher noise levels and lower precision compared to metal film resistors.

2. Wirewound Resistors

Wirewound resistors consist of a wire wound around a core. They can handle higher power ratings but are bulkier and less precise than metal film resistors, making them less suitable for applications requiring high accuracy.

III. Electrical Characteristics

A. Resistance Value Range

Metal film resistors are available in a wide range of resistance values, typically from a few ohms to several megaohms. This versatility allows them to be used in various applications, from simple circuits to complex instrumentation.

B. Tolerance Levels

1. Standard Tolerances (1%, 5%)

Standard metal film resistors typically have tolerances of 1% or 5%, making them suitable for general-purpose applications where moderate precision is acceptable.

2. Precision Tolerances (0.1%, 0.5%)

For applications requiring high accuracy, precision metal film resistors are available with tolerances as low as 0.1% or 0.5%. These resistors are essential in precision measurement and calibration tasks.

C. Temperature Coefficient of Resistance (TCR)

1. Definition and Importance

The temperature coefficient of resistance (TCR) indicates how much a resistor's resistance changes with temperature. A low TCR is desirable as it ensures stable performance across varying temperatures.

2. Typical Values for Metal Film Resistors

Metal film resistors typically have a TCR of ±5 to ±50 ppm/°C, making them suitable for applications where temperature stability is critical.

IV. Performance Features

A. Stability and Reliability

1. Long-term Stability

Metal film resistors exhibit excellent long-term stability, meaning their resistance values remain consistent over time, even under varying environmental conditions.

2. Environmental Stability

These resistors are also resistant to environmental factors such as humidity and temperature fluctuations, ensuring reliable performance in diverse applications.

B. Noise Characteristics

1. Low Noise Generation

One of the standout features of metal film resistors is their low noise generation. This characteristic is particularly important in audio and precision measurement applications, where noise can significantly impact performance.

2. Comparison with Other Resistor Types

Compared to carbon film and wirewound resistors, metal film resistors produce significantly less noise, making them the preferred choice for high-fidelity audio and sensitive electronic circuits.

C. Power Rating

1. Power Dissipation Capabilities

Metal film resistors are available in various power ratings, typically ranging from 1/8 watt to several watts. This range allows them to be used in both low-power and moderate-power applications.

2. Heat Management

Effective heat management is crucial for maintaining performance. Metal film resistors are designed to dissipate heat efficiently, reducing the risk of thermal damage and ensuring longevity.

V. Applications

A. Common Uses in Electronics

1. Audio Equipment

Metal film resistors are widely used in audio equipment due to their low noise characteristics and high precision, contributing to better sound quality.

2. Precision Measurement Instruments

Instruments that require accurate measurements, such as oscilloscopes and multimeters, often utilize metal film resistors for their stability and precision.

B. Specialized Applications

1. Medical Devices

In medical devices, where accuracy and reliability are paramount, metal film resistors are commonly employed to ensure precise readings and safe operation.

2. Aerospace and Defense

The aerospace and defense industries rely on metal film resistors for their robustness and stability in extreme conditions, making them suitable for critical applications.

C. Trends in Usage

As technology advances, the demand for high-precision components continues to grow. Metal film resistors are increasingly being integrated into modern electronic designs, particularly in fields such as IoT and automotive electronics.

VI. Advantages of Metal Film Resistors

A. High Precision and Accuracy

Metal film resistors are known for their exceptional precision, making them ideal for applications where accuracy is critical.

B. Low Temperature Coefficient

Their low TCR ensures stable performance across a wide temperature range, enhancing reliability in various environments.

C. Excellent Stability Over Time

With long-term stability, metal film resistors maintain their performance characteristics, reducing the need for frequent recalibration.

D. Versatility in Applications

The wide range of resistance values and power ratings makes metal film resistors suitable for diverse applications, from consumer electronics to industrial equipment.

VII. Limitations of Metal Film Resistors

A. Cost Considerations

While metal film resistors offer numerous advantages, they are generally more expensive than carbon film resistors, which may be a consideration for budget-sensitive projects.

B. Power Handling Limitations

Metal film resistors have lower power handling capabilities compared to wirewound resistors, making them less suitable for high-power applications.

C. Size Constraints

Although they are available in various sizes, metal film resistors can be bulkier than other types, which may pose challenges in compact circuit designs.

VIII. Conclusion

A. Summary of Key Features

Metal film resistors are characterized by their precision, stability, low noise generation, and versatility. Their construction and electrical characteristics make them a preferred choice in many high-performance applications.

B. Future Trends in Metal Film Resistor Technology

As electronic devices continue to evolve, the demand for high-precision components will likely increase. Innovations in manufacturing processes and materials may further enhance the performance and applicability of metal film resistors.

C. Final Thoughts on Selection and Use in Circuit Design

When selecting resistors for electronic circuits, engineers must consider the specific requirements of their applications. Metal film resistors offer a reliable solution for applications demanding high accuracy and stability, making them an excellent choice for modern electronic designs.

IX. References

A. Suggested Reading

1. "Resistor Technology: A Comprehensive Guide" - Electronics Journal

2. "Understanding Resistor Types and Their Applications" - Circuit Basics

B. Industry Standards and Guidelines

1. IEC 60115 - Resistors for use in electronic equipment

2. EIA-198 - Standard for Resistor Specifications

By understanding the product features of metal film resistors, engineers and designers can make informed decisions that enhance the performance and reliability of their electronic circuits.